Kinetic Energy Recovery Systems: Unleashing Efficiency in Motorsports

In the high-octane world of motorsports, where every millisecond counts, engineers are constantly pushing the boundaries of technology to gain a competitive edge. One innovation that has revolutionized racing in recent years is the Kinetic Energy Recovery System, commonly known as KERS. This groundbreaking technology has not only enhanced performance on the track but also paved the way for more sustainable racing practices. As we delve into the intricacies of KERS, we'll explore its origins, mechanics, and the profound impact it has had on the world of motorsports.

In 2009, Formula 1 introduced KERS as an optional system, marking a significant milestone in motorsport technology. Initially, teams struggled with reliability issues and added weight, but as the technology matured, its benefits became increasingly apparent. The system’s ability to provide short bursts of extra power proved invaluable for overtaking maneuvers and defending positions on the track.

How KERS Works: A Symphony of Mechanical and Electrical Engineering

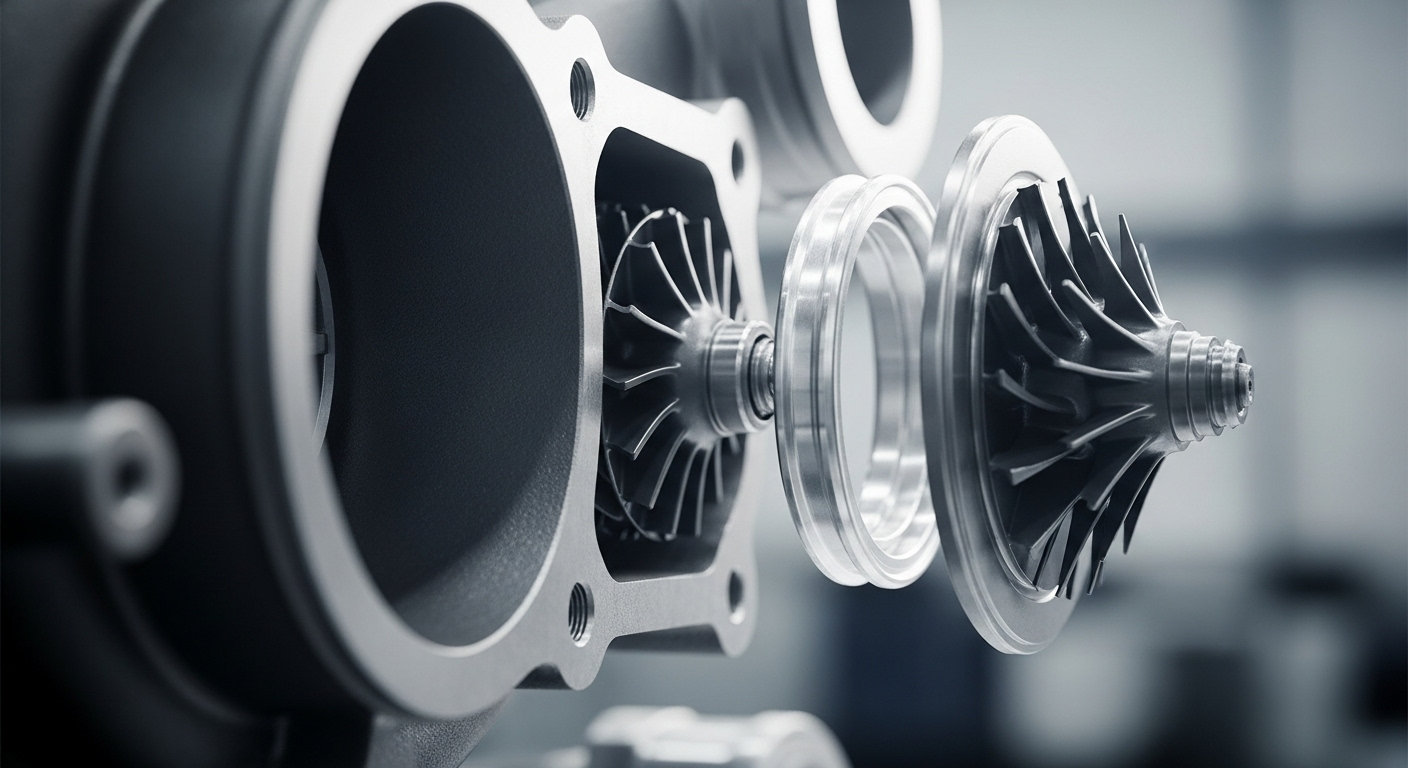

At its core, KERS operates on a simple principle: converting kinetic energy into storable power. When a race car decelerates, the system captures a portion of the energy that would typically be lost as heat through the brakes. This energy is then converted and stored, ready to be deployed at the driver’s discretion.

There are two primary types of KERS: electrical and mechanical. Electrical KERS uses a motor-generator unit connected to the drivetrain. During braking, this unit acts as a generator, converting kinetic energy into electrical energy stored in a battery pack. When activated, the stored energy is released back through the motor, providing an additional power boost to the wheels.

Mechanical KERS, on the other hand, utilizes a flywheel system. As the car slows down, the flywheel spins up, storing rotational energy. When extra power is needed, this energy is transferred back to the wheels through a continuously variable transmission (CVT). While less common than its electrical counterpart, mechanical KERS offers unique advantages in terms of response time and energy density.

The Impact on Racing Strategy and Performance

The introduction of KERS has dramatically altered racing dynamics, particularly in Formula 1. Drivers now have an additional tactical tool at their disposal, allowing for more strategic overtaking and defensive maneuvers. The ability to deploy stored energy at critical moments, such as at the start of a race or when exiting corners, has added a new layer of complexity to race strategy.

Furthermore, KERS has contributed to improved lap times and overall race performance. The extra power boost, typically around 80 horsepower for up to 6.7 seconds per lap in Formula 1, can make a significant difference in a sport where fractions of a second can determine the outcome of a race.

Beyond Formula 1: KERS in Other Motorsports

While Formula 1 pioneered the use of KERS in high-level motorsports, the technology has since found applications in other racing series. Endurance racing, in particular, has embraced energy recovery systems as a means to improve efficiency over long distances. The FIA World Endurance Championship, including the prestigious 24 Hours of Le Mans, has integrated hybrid powertrains that utilize similar principles to KERS.

In rallycross, a modified version of KERS known as electric supercharging has been implemented. This system uses electric motors to spool up turbochargers, eliminating turbo lag and providing instant power delivery. The result is improved acceleration and more responsive performance, crucial in the short, intense races characteristic of rallycross.

Challenges and Continuous Innovation

Despite its advantages, KERS implementation has not been without challenges. Early systems added significant weight to vehicles, potentially offsetting performance gains. Reliability issues were also a concern, with teams initially struggling to integrate the complex technology seamlessly into their cars.

However, continuous innovation has addressed many of these initial hurdles. Modern KERS units are lighter, more reliable, and increasingly efficient. Engineers have focused on optimizing energy capture and deployment, as well as improving the integration of KERS with other vehicle systems.

The Future of KERS: From Track to Street

As KERS technology matures in the motorsport arena, its potential applications extend beyond the racetrack. The principles behind KERS align closely with those used in hybrid and electric vehicles for everyday use. Technologies developed for racing are often precursors to innovations in consumer vehicles, and KERS is no exception.

Some high-performance road cars have already incorporated KERS-inspired systems, offering drivers a taste of racing technology in their daily drives. As the automotive industry shifts towards more sustainable practices, the lessons learned from KERS development in motorsports could play a crucial role in improving the efficiency and performance of future road vehicles.

In conclusion, Kinetic Energy Recovery Systems have transformed the landscape of motorsports, offering a perfect blend of performance enhancement and energy efficiency. From its inception in Formula 1 to its adoption across various racing disciplines, KERS continues to evolve, pushing the boundaries of what’s possible in automotive engineering. As we look to the future, the impact of this innovative technology is likely to extend far beyond the racetrack, potentially revolutionizing the way we think about energy use in all forms of transportation.