Adaptive Manufacturing: Reshaping Production Dynamics

As industries grapple with rapidly changing market demands, adaptive manufacturing emerges as a game-changing approach. This innovative methodology allows production systems to swiftly respond to fluctuations in consumer preferences, supply chain disruptions, and technological advancements. By integrating flexibility and responsiveness into core manufacturing processes, companies can optimize their operations, reduce waste, and stay ahead of the competition in an increasingly volatile business landscape.

The key principles of adaptive manufacturing include:

-

Modular production units

-

Real-time data analytics

-

Flexible automation systems

-

Rapid prototyping and iteration

-

Cross-trained workforce

These elements work in concert to create a manufacturing ecosystem that can pivot quickly in response to external factors, without sacrificing efficiency or quality.

The Role of Advanced Technologies

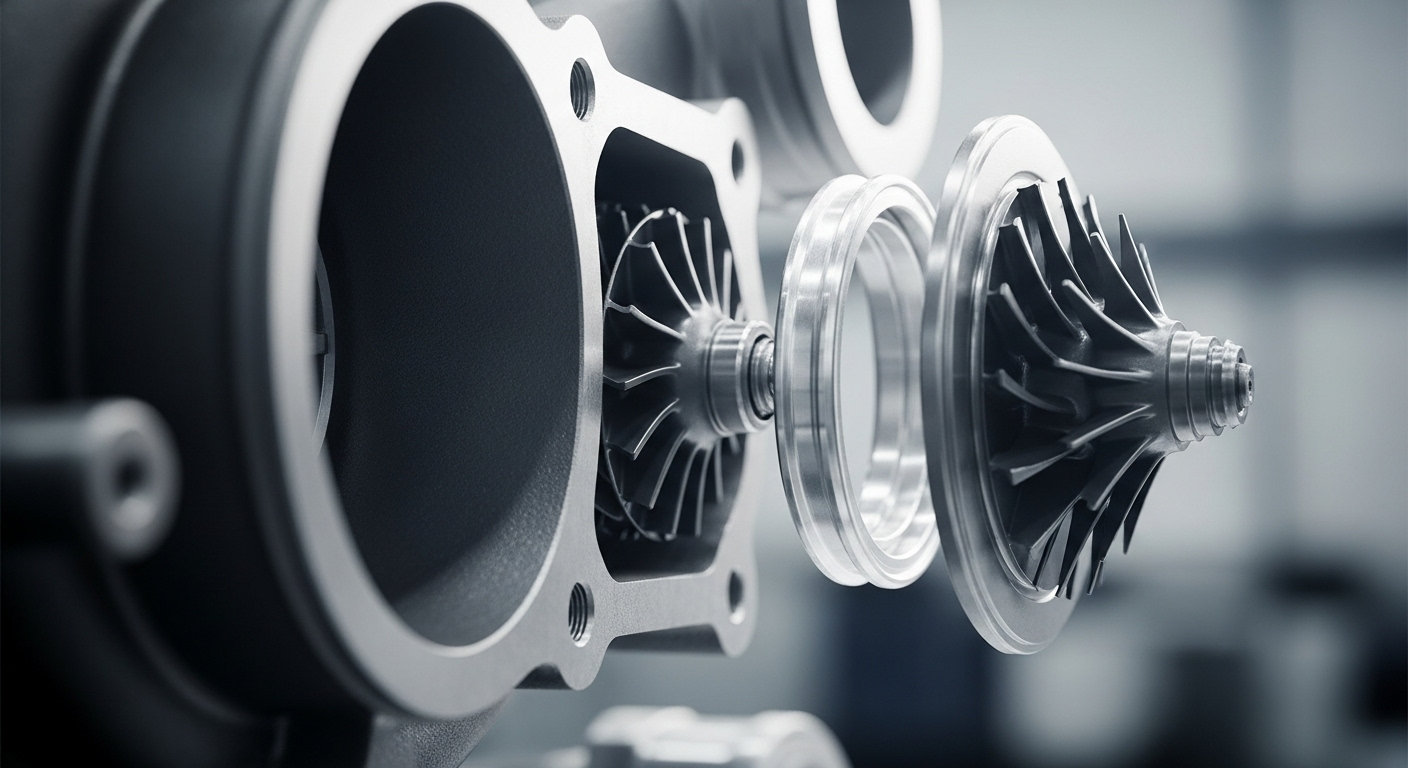

At the heart of adaptive manufacturing lies a suite of cutting-edge technologies that facilitate rapid change and informed decision-making. Machine learning algorithms analyze vast amounts of production and market data to predict trends and optimize processes in real-time. Additive manufacturing techniques, such as 3D printing, allow for quick prototyping and small-batch production of customized parts. Collaborative robots, or cobots, work alongside human operators, easily reprogrammed to handle different tasks as needed.

Moreover, the integration of Industrial Internet of Things (IIoT) devices throughout the production floor provides a constant stream of data, offering unprecedented visibility into every aspect of the manufacturing process. This data-driven approach enables manufacturers to identify bottlenecks, predict maintenance needs, and make informed decisions about resource allocation.

Implementing Adaptive Manufacturing Strategies

Transitioning to an adaptive manufacturing model requires a significant shift in both mindset and infrastructure. Companies must be willing to invest in new technologies and training programs while also reimagining their organizational structures to promote agility and cross-functional collaboration.

One effective strategy is to start with a pilot program in a single production line or facility. This allows organizations to test and refine their adaptive approaches before rolling them out across the entire operation. Key steps in implementation include:

-

Conducting a thorough assessment of current production capabilities and limitations

-

Identifying areas where flexibility would provide the greatest benefit

-

Investing in modular equipment and reconfigurable production spaces

-

Developing a robust data infrastructure to support real-time decision-making

-

Training employees in multiple disciplines to create a more versatile workforce

As the pilot program proves successful, companies can gradually expand their adaptive manufacturing initiatives, scaling up to encompass larger portions of their operations.

The Impact on Supply Chain Management

Adaptive manufacturing has far-reaching implications for supply chain management. By enabling more responsive production capabilities, companies can reduce their reliance on large inventories and long-term forecasts. Instead, they can operate with leaner inventories and shorter lead times, adjusting production in near real-time to match actual demand.

This shift towards a more agile supply chain model can lead to significant cost savings and improved customer satisfaction. It also enhances a company’s ability to weather supply chain disruptions, as production can be quickly redirected or reconfigured to accommodate changes in material availability or shipping routes.

Challenges and Considerations

While the benefits of adaptive manufacturing are substantial, implementing this approach is not without its challenges. Some key considerations include:

-

High initial investment costs for new technologies and equipment

-

The need for extensive employee training and potential resistance to change

-

Cybersecurity concerns associated with increased connectivity and data sharing

-

Complexity in managing highly flexible production systems

-

Balancing customization with economies of scale

Companies must carefully weigh these factors against the potential benefits and develop comprehensive strategies to address each challenge.

Adaptive Manufacturing Insights

• Start small: Begin with a pilot program to test and refine adaptive strategies before full-scale implementation.

• Invest in cross-training: Develop a versatile workforce capable of handling multiple roles within the production process.

• Prioritize data integration: Establish a robust data infrastructure to enable real-time decision-making and process optimization.

• Embrace modularity: Design production systems and spaces that can be easily reconfigured to accommodate changing needs.

• Foster a culture of innovation: Encourage employees at all levels to contribute ideas for improving flexibility and responsiveness.

As industries continue to evolve in the face of global challenges and technological advancements, adaptive manufacturing stands out as a crucial strategy for maintaining competitiveness. By embracing flexibility, leveraging advanced technologies, and fostering a culture of continuous improvement, manufacturers can position themselves to thrive in an increasingly dynamic business environment. The journey towards adaptive manufacturing may be complex, but the potential rewards in terms of efficiency, responsiveness, and innovation make it a compelling path forward for forward-thinking companies.